Updated May 5, 2022

Greenhouse gas emissions from transportation and industry are among the most challenging to mitigate, in part because electrification of many end uses in these sectors is not yet possible. For these applications, the environmentally responsible use of biofuels provides a robust and potentially rapid approach to reducing climate impacts. In particular, the renewable diesel industry is poised for rapid growth, and its product can function as a drop-in substitute to replace fossil fuel-derived diesel refined from crude oil. Renewable diesel has attracted the attention of the Oregon legislature and could soon become an important part of our energy mix.

Renewable diesel is a type of biofuel made primarily from oil-rich crops like soybeans, canola, camelina and flax (linseed), but can also be sourced from waste oils and animal fats. Renewable diesel is one of two types of diesel biofuel. The other is confusingly named “biodiesel” – a term so general that it suggests it is the only kind of product the oil-rich crops can yield. Whereas “renewable diesel” and “biodiesel” do come from the same source materials, or “feedstocks,” they differ in how those feedstocks are processed on the way to the final products, yielding two distinct types of crop-based diesel fuel with markedly different properties.

“Biodiesel” is made by reacting plant or animal-derived oils with methanol, or wood alcohol, a poisonous cousin of the ethanol in alcoholic beverages. The reaction generates a group of molecules called fatty acid methyl esters, or FAME, which is just the oil hydrocarbon with a small chemical group (an ester) hanging off the end. Unfortunately, while the FAME product is stable and can be stored like conventional diesel fuel, leftover methanol from the reaction lowers the flash point of the fuel, increasing flammability and making it unsafe and unreliable to use in pure form. So “FAME biodiesel” needs to be blended with fossil petroleum diesel, and the maximum safe blending ratio is only 20%. You can see this at a diesel fuel pump in the form of a label indicating “B20”. This means that, even though FAME biodiesel is an improvement over conventional diesel fuel, it still contains at least 80% fossil fuel. The reduced carbon pollution comes only from the 20% blended part.

Unlike FAME biodiesel, the huge benefit of renewable diesel is that it does not suffer from safety and reliability issues, and is approved as a 100% drop-in replacement for petroleum diesel for all applications. When you buy renewable diesel, the benefit in the form of reduced carbon dioxide emissions comes from the entire product, not just 20% of it. Another major benefit is that existing petroleum diesel production facilities can be retrofitted into renewable diesel plants. This allows renewable diesel to grow more rapidly while preserving oil and gas industry jobs and offering fossil fuel companies an opportunity to contribute to the new renewable energy economy.

All biofuels are not alike

Some climate advocates are wary of biofuels because of some painful failures made in this area of energy policy. The US has a renewable fuels law that applies to the whole country, which is why gasoline is blended with 10% ethanol, almost all made by fermentation from corn. But much of that ethanol is produced in ways that provide little to no climate benefit, with many old plants exempt from delivering even modest emissions reductions. Worse, some of the imported biodiesel allowed under the law was derived from plantations in Indonesia and Malaysia. In those countries, rainforests were decimated and indigenous communities displaced to make palm oil for hungry US markets.

All biofuels, however, are not alike, and many can be made in environmentally responsible ways that reduce climate pollution compared with fossil fuels. Looking at the big picture of crude oil use in the US, in 2019 nearly half the consumption of 315 billion gallons of crude oil went into gasoline for cars and light trucks. This is combined with 10% corn ethanol, but the rapid rise of electric cars means that both gasoline and ethanol will likely soon enter a terminal decline. Another 30% of the crude oil is refined to produce a huge array of other products, including aircraft fuel, lubricants, plastics, consumer products of every type, and much more. There will certainly be opportunities for renewable biodiesel to penetrate that part of the crude oil market, but what concerns us here is the remaining 20% of the crude – about 63 billion gallons per year of diesel fuel, used in transportation (rail, buses, maritime shipping, construction equipment, heavy trucking, military transport) and in the industrial, residential and commercial sectors. This is where renewable diesel comes into its own.

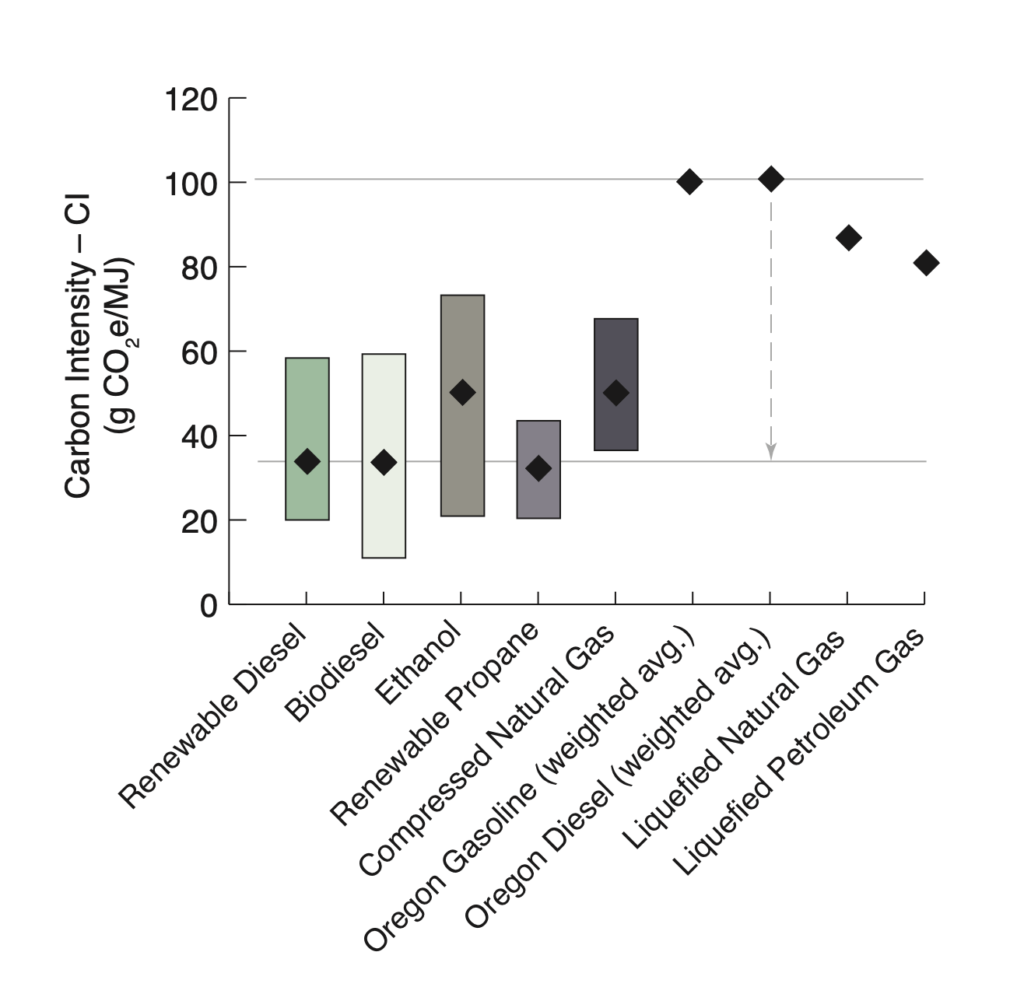

The climate benefits of renewable diesel are estimated with a number called the carbon intensity (CI), which indicates how much carbon dioxide is emitted to generate a given amount of energy, expressed in grams of CO2 per megajoule. CIs are determined by life-cycle analysis, which tracks the energy requirements and carbon emissions of a product through its entire life cycle. For renewable diesel, there is no net carbon pollution from burning the fuel because all the carbon comes from the crop – which, unlike forests, fully regrows within a year or less. Carbon reductions are also achieved through co-products made from the crop (such as glycerin from soybeans), which would otherwise come from fossil petroleum. However, the crop biomass has to be planted, harvested and processed, the oil extracted and refined, and the final product transported to the site of use. That costs energy and thus results in some CO2 emissions, but only about 35% as much as fossil diesel generates. The CI includes carbon pollution from making the hydrogen gas needed in refinement, and necessary soil supplements for farming. The actual carbon emissions vary somewhat with the crop and where it is produced and used, so the 65% savings is an average value (see the Figure).

Renewable diesel gets a big boost in Oregon from Governor Brown’s 2020 executive order that established the Oregon Climate Action Plan, including a Clean Fuels Program (CFP) modeled after California’s successful Low Carbon Fuels Standard (LCFS). The CFP was initiated in 2016 and targets a 25% reduction in transportation emissions by 2035. Renewable diesel can make a significant contribution to meeting this target.

Under the CFP, Oregon fuel refiners and importers have to reduce the carbon content of their fuels according to a strict emissions reduction timetable. The program creates a market for low carbon fuels in which the refiners purchase credits from the biofuel producers, with each credit corresponding to a specified reduction in emissions. The producers submit proposed pathways for fuel production to the CFP, which returns a CI value when it approves their proposal. This sets the value of the credit in terms of how much emissions reduction a particular fuel pathway provides. There are already 37 approved pathways for renewable diesel in California, and 24 approved pathways in Oregon. The LCFS and CFP encourage producers everywhere to sell greener fuels into these markets, rewarding innovation in direct proportion to the climate friendliness of the new technology.

Liquid biofuels or electrification?

The Oregon Climate Action Plan envisions dramatic emissions reductions in the next few decades, with greening of the electric power grid and electrification of end uses leading the way. Indeed, “electrify everything” is often taken as an organizing principle for the renewable energy transition. But while rapid electrification is clearly crucial to meeting climate targets, there are many applications for which the technology to accomplish this will simply not be available at scale for decades – if ever. These include aviation, shipping, railroads, and delivery of heat to high-temperature industrial processes such as steelmaking, pulp and paper production, and cement manufacturing. For these end uses, renewable diesel offers a powerful way to reduce legacy emissions and thus lower the quantity of carbon dioxide that will eventually have to be removed from the atmosphere. In contrast, some large diesel consumers, such as TriMet’s buses, need only use renewable diesel for the time it will take to convert the diesel fleet to already-available electric buses.

The calculated CO2 emissions reductions from renewable diesel and other biofuels are robust, detailed estimates founded on broad scientific agreement. Yet all technologies that provide climate benefits also can have detrimental impacts that implicate concerns apart from carbon pollution. Renewable diesel crops require substantial dedication of agricultural land, and their cultivation may contribute to soil degradation, overuse of pesticides and fertilizers, and land use change in the long term. Depending on the type of crop, substantial amounts of water may be required for irrigation. And like any intensive land use, all large scale agriculture has the potential to impact local ecology, biodiversity and human rights. Possible effects on food prices and any long-term impacts on land carbon stores, especially for imported fuel, will also need to be carefully watched.

Many key questions confront Oregon lawmakers as they consider how best to reduce consumption of petroleum diesel below the over 700 million gallons burned here in 2019. Should Oregon farmers be encouraged to dedicate land specifically to cultivating crops for renewable diesel, and, if so, what is the best policy to accomplish this? Will oil-rich cover crops on existing Oregon farmland suffice to meet our needs, or can we also bring new land into cultivation while avoiding serious impacts on native ecology or water resources? What are realistic targets for renewable diesel production from Oregon lands, given typical yields of oil per acre? New laws and regulations to address these and other questions will also need to dovetail with the Oregon Clean Fuels Program, presently the subject of a rulemaking to expand the reach of the law. Finally, the new NEXT Renewable Fuels refinement plant in Port Westward, scheduled to open in 2024, is large enough to replace all of Oregon’s petroleum diesel consumption with renewable diesel. How can we create the greenest possible supply chains for this facility?

With the right policies in place, renewable diesel can make a significant contribution to reducing greenhouse gas pollution, while developing in-state capacities for crop deployment and fuel refining may also provide economic and employment benefits to Oregon. This technology is worth the support and attention of any climate advocate interested in tackling emissions from the difficult industrial and transportation sectors.